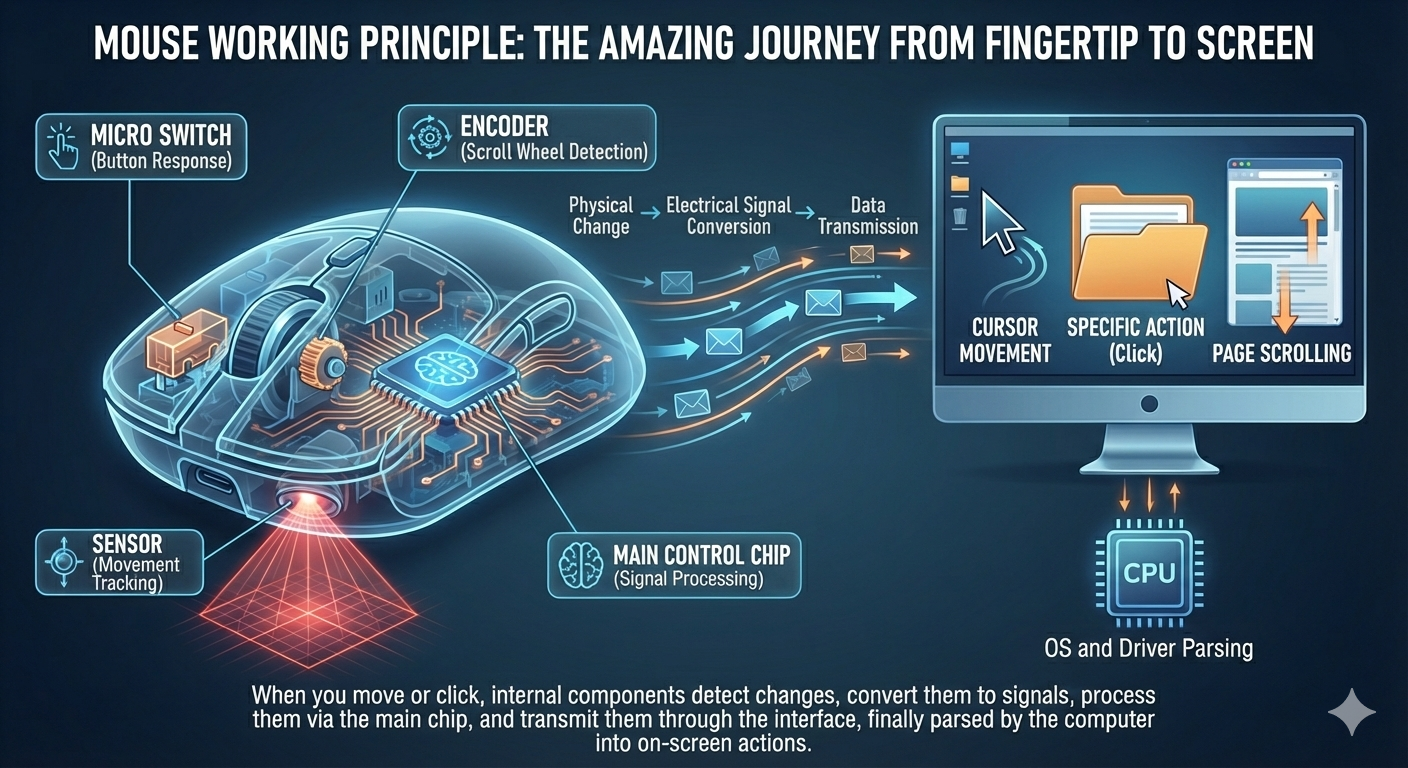

Basic Mouse Working Principle

As one of the most important computer input devices, the mouse's core function is to convert hand movements into digital signals that computers can understand. Regardless of mouse type, the basic working principle involves these key steps:

Mouse Working Process Flowchart

(Hand movement/Clicking)

(Optical/Mechanical)

(Analog→Digital)

(USB/Wireless)

(Driver software)

When you move the mouse or press buttons, internal sensors detect these physical changes, convert them into electrical signals, transmit them through the interface to your computer, and finally the operating system and drivers interpret them as cursor movement or specific actions on screen.